Automotive Water Pump Impeller Design

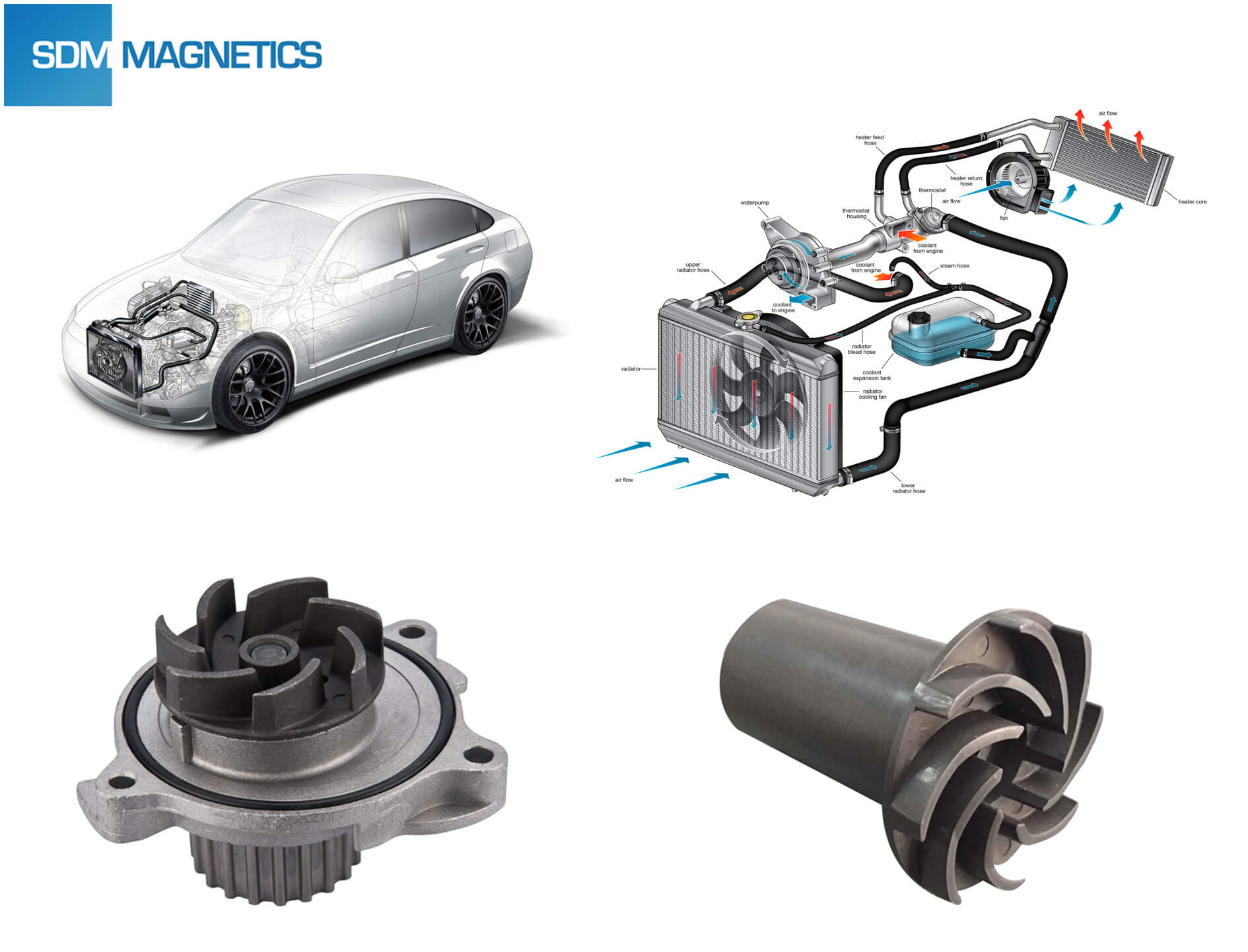

A worn impeller on a water pump can reduce the amount of coolant flow through the engine.

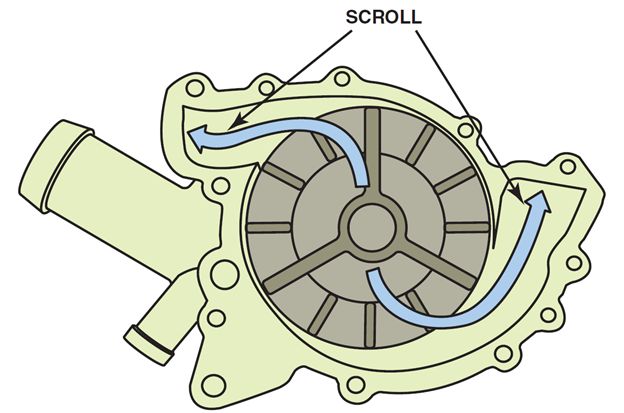

Automotive water pump impeller design. Typically these days water pumps come with plastic impellers to fit design parameters and keep costs down however we often recommend upgrading to a new water pump with a metal impeller for most applications when available. If the seal of the water pump fails coolant will leak out of the weep hole. The car is known for an insufficient stock cooling system 2. L to r open semi closed and enclosed shrouded.

Not good for coolant circulation. Upon closer inspection it is clear that the impeller has completely separated from the shaft. By fitting the vane ends very close to the pump casing the open impeller is able to prevent large amounts of fluid or gas from recirculating back through the eye. The animations were a huge help.

Automotive pump and fan system design. 7 comments on water pump design. 12v pumps and fans. Please choose a subcategory.

You can also choose from full vortex semi open and open vortex water pump impeller design as well as from diesel water pump impeller design and whether water pump impeller design is piston pump single stage pump or. Fortron pps selected by airtex to gain design freedom mechanical integrity for auto water pump impellers in aggressive coolants when airtex products in fairfield illinois usa developed six new water pumps for cars made by u s. Now a shop is producing a water pump replacement that has an impeller built from cnc d billet aluminum. Open impellers simply consist of a series of vanes attached to a central hub designed to be fitted to a shaft.

The crucial water pump parameters are the head power and its efficiency. The hole allows coolant to escape without getting trapped and forced into the water pump bearing. July 2018 at 20 48. It is amazing the amount of engineering that went through on this.

July 2018 at 07 09. Whether electric or fuel powered luxury or economy class vehicles today are equipped with increasingly more systems that rely on a wide range of motor control applications. This was a good read that was informative and easy to understand. The hole allows coolant to escape without getting trapped and forced into the water pump bearing assembly.

Fortron pps from ticona the technical. This car did over heat and. 1 given that this car was considered to be a very well sorted sports car why would the oem still use a stamped design that cavitates. Geometry for a shrouded impeller andy lee 12.

Friendship systems post author 13. Design solutions for integrated automotive engine control systems for pumps and fans. Supposedly it does not see significant cavitation all the way up to red line. Automakers it chose fortron polyphenylene sulfide pps for its impellers rather than aluminum or cast iron.